Breadcrumb

PGMA

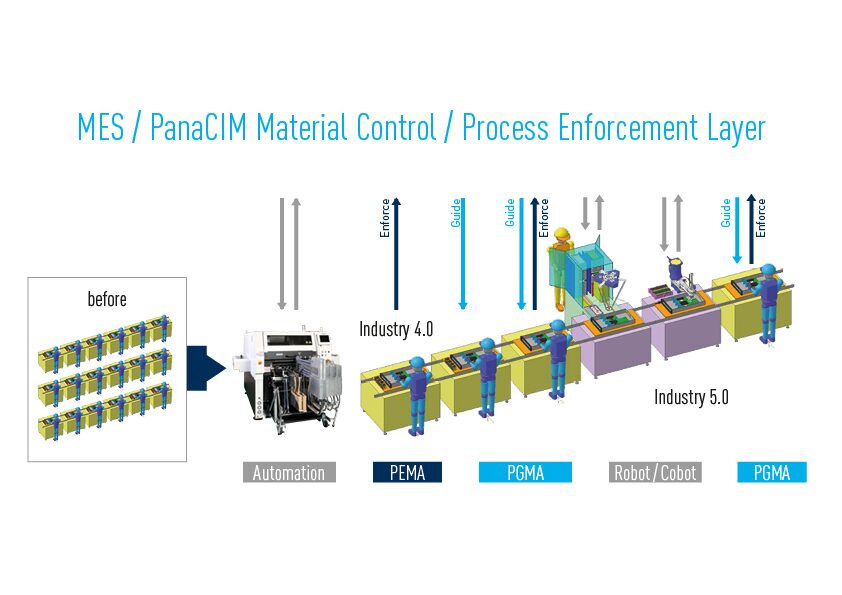

Panasonic Guided Manual Assembly

helps to enhance manual assembly

PGMA - Panasonic Guided Manual Assembly helps to enhance manual assembly

- to avoid any mistakes while assembly

- to ensure an effective “zero-defect strategy”

- to share knowhow by organizing work instruction and work flows

- to introduce full traceability

- to apply an effective end-to-end material management

| Guidance | Enforcement | |

| Key Values | Increase operator's efficiency Get the assembly more reliable Improve product quality by higher yield | Traceability Material Management |

| Features |

Sharing and accumulate knowledge & know-how Avoid errors and increase motivation Cost saving by reducing error factor | Connection to MES and/or ERP system Provide "just-in-time" required materials automatically Manual assembly included in the reporting loop Cost saving by more efficient production and material planning |

Typical use-cases for PGMA to guide & enhance are:

- Manual THT insertion

- Manual mechanical assembly

- Semiautomatic screw & nut mounting with and without torque control

- Manual visual inspection

- Semiautomatic testing and/or measurement

- Manual product packing and labelling incl. weight control (optional)

- Training for any manual assembly & activity

The ROI (return of invest) period for PGMA implementation is typically much less than one year due to reduction of failures and mistakes, speeding up the assembly process and finally increase of user‘s motivation.

Key features of PGMA

Key features

| avoid any mistakes during assembly |

| ensure an effective “zero-defect strategy” |

| share knowhow by organizing work instruction and work flows |

| introduce full traceability |

| apply an effective end-to-end material management |

Features, Modules & Systems

- Controller as computer unit:

- for guidance setup & work instruction administration

- as central data storage

- incl. hardware interfaces and control

- Connection to MES and/or ERP system

- Interface to PanaCIM Material Control for „just-in-time“ material preparation

- Panasonic laser projector for visualization

- High-resolution camera with high-intensity lighting as AOI

- Touch Panel as GUI (General User Interface)

- Monitor for local reporting / traceability of production data

- Material boxes with Pick2light functionality

- Barcode reader

- Workplace table incl. suitable holders and fixtures

- Conveyer with SMEMA interface

- Typical size (depends on configuration): W x D x H = 1,0 m x 1,2 m x 2,80 m

- Weight: (depends on configuration): 200 kg

Panasonic Guided Manual Assembly

Specifications of PGMA

Specifications table

| Controller as computer unit | for guidance setup & work instruction administration as central data storage incl. hardware interfaces and control |

|---|---|

| Other | Connection to MES and/or ERP system Interface to PanaCIM Material Control for „just-in-time“ material preparation Panasonic laser projector for visualization High-resolution camera with high-intensity lighting as AOI Touch Panel as GUI (General User Interface) Monitor for local reporting / traceability of production data Material boxes with Pick2light functionality Barcode reader Workplace table incl. suitable holders and fixtures Conveyer with SMEMA interface |

| Size | Typical size (depends on configuration): W x D x H = 1,0 m x 1,2 m x 2,80 m |

| Weight | (depends on configuration): 200 kg |

Share page

Share this link via:

Twitter

LinkedIn

Xing

Facebook

Or copy link: