Breadcrumb

Dry Etcher

APX300

The APX300 (option S) Dry Etcher is the perfect dry etching equipment for silicon and compound semiconductors.

Key features of APX300 Dry Etcher

Key features

| Two plasma sources available |

| Atmospheric Loading Supply |

| Vacuum Load Lock Supply |

| Covers wide range of process demands |

The APX300 (option S) Dry Etcher is the perfect dry etching equipment for silicon and compound semiconductors. It incorporates a multi-wafer direct cooling system for optimal control of wafer temperature, as well as MSC-ICP (Multi-Spiral Coil type ICP) and BM-ICP (Beamed-type ICP) plasma sources to generate high density plasma. In this way, it achieves a uniform etching profile in a very short timeframe.

Building upon the single wafer process chamber of the previous model (Panasonic E620), combined with enhanced process options and two different handling systems, the APX300 (option S) is extremely fast and covers a wide range of process demands.

Features and benefits of Panasonic's APX300 (option S) Dry Etcher

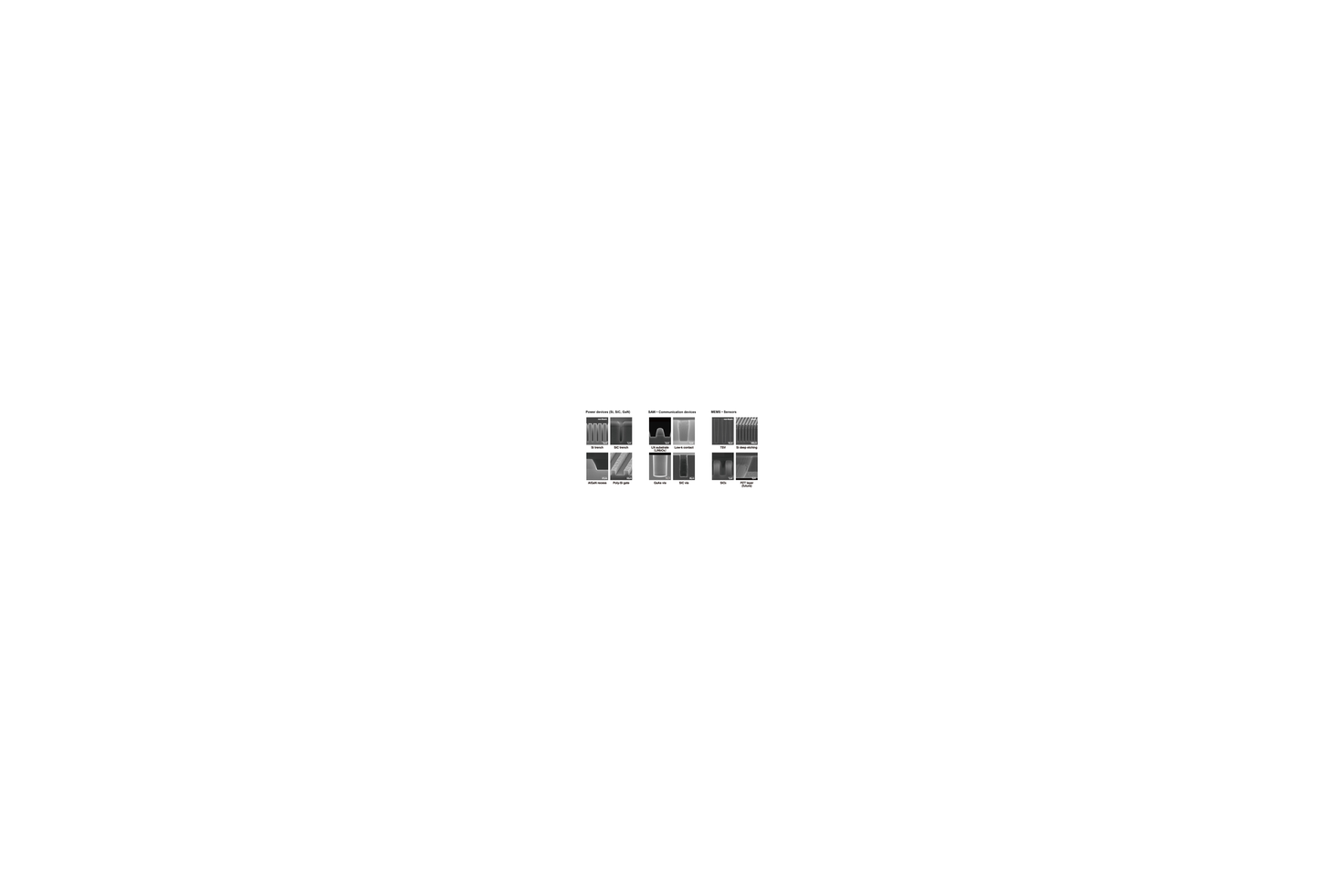

The Panasonic APX300 (option S) Dry Etcher can process wafers such as power devices, SAW filters, communication devices, MEMS sensors and many more. The APX300 (option S) is the successor to the previous best-selling Panasonic E620 and utilizes the same single wafer process chamber.

Two plasma sources are available: MSC-ICP (Multi-Spiral Coil type ICP) and BM-ICP (Beamed-type ICP). MSC-ICP is Panasonic's latest technology, developed to realize highly accurate processing. BM-ICP offers higher electron density and achieves faster processing, covering a wide range of process demands.

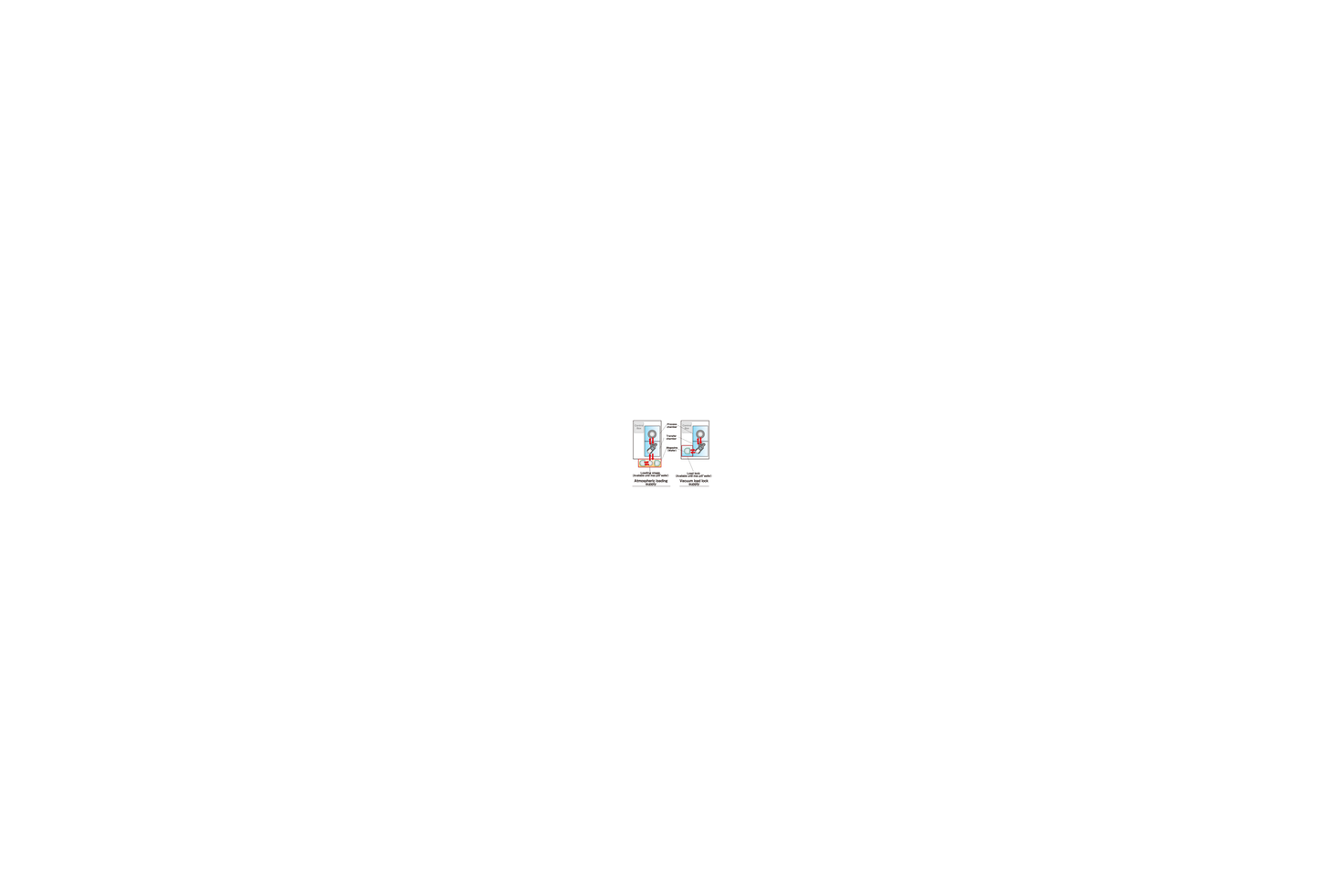

In addition, two types of handling systems are available: Atmospheric Loading Supply and Vacuum Load Lock Supply.

The Panasonic APX300 (option S) Dry Etcher is CE certified.

Specifications of APX300 Dry Etcher

Specifications table

| Dimensions (mm) | [Load lock wafer Handling] W 1350 x D 2230 x H 2000 (Exclude touch panel, operation section and signal tower) [Load lock wafer Handling] W 1375 x D 2600 x H 2000 (Exclude touch panel, operation section and signal tower) |

|---|---|

| Plasma source | ICP Plasma |

| Model-No. (Model Name) | NM-EFE3AA-S |

| Process gas | Standard 4 lines (Maximum 6 Lines: Chlorinated Gas, Fluoride Gas, Ar, O2, He, etc.) |

| Wafer size | Ø100mm / 150mm wafer with orientation flat Ø200mm wafer with notch *Please consult, if different size of wafer will be required. |

| Mass (Weight) | 2000kg (Differs depending on machine configuration) |

| Power Source | 3-phase AC 200 / 208 / 220 / 230 / 240 ±10 V, 50 / 60Hz, 21.00kVA *3-phase electricity has two kinds of lineage. Figure shows total. |

| Pneumatic Source | 0.5MPa to 0.7MPa, 250L/min (A.N.R.) |

Share page

Share this link via:

Twitter

LinkedIn

Xing

Facebook

Or copy link: